Many industrial applications require components that are durable and stable. There is no tolerance for deformation or breakage. Can 3D printed parts be used for applications of this kind? We are convinced: yes, they can!

By inserting continuous technical fibers, the 3D printed parts made of thermoplastic materials are reinforced in such a way that they can withstand high industrial loads. Deformations are reduced and long-term stability is guaranteed. These reinforcements open up a wide range of possibilities and can be optimized depending on the area of application.

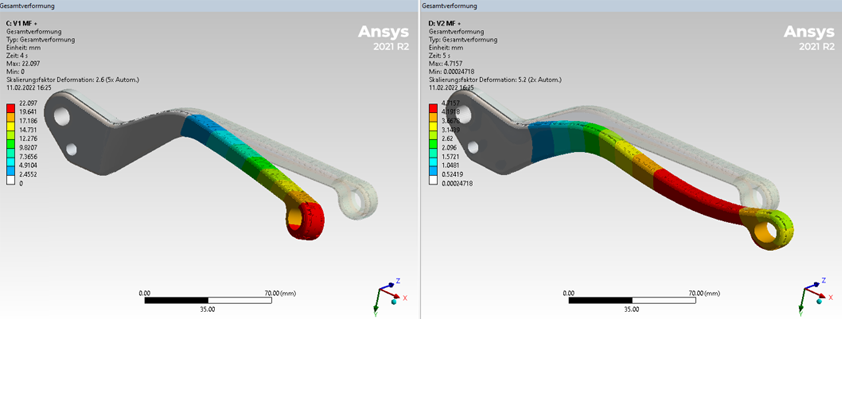

FEM Calculations Provide Security

Even before actual production, we are able to calculate the rigidity of the planned components using modern FEM methods. This not only saves time compared with the process of trial and error, but there are also other advantages:

- Qualified forecast of possible deformations and component behavior

- The results show where the weak spots in the component are

- Qualified possibility of optimizing the components, both with regard to the component’s geometry and in the arrangement of the layers/ fibers

Find out more about the services we provide in the area of additive production.