Service Bulletin July 2022

- P-455 Machine with New BR PC-3100

- New Employees in the Service Sector

- Measures for long-time stops of wire-forming machines

- Travel Restrictions Largely Lifted

- Inspection Protocol Goes Digital

- Monitoring & Analytics

With the new BR PC-3100 conversion kit for P-455, including control unit article no. 31.47043.01, the Beckhoff and Visual PC are replaced by the BR PC and at the same time equipped with a Christ monitor. The machine therefore now has the latest control generation, and a possible source of error has been eliminated. If you are interested, please send an email to spareparts(at)spuhl.com and we will be happy to send you an offer.

Karina Iacomucci

After receiving intensive training at Spühl in Wittenbach, Karina has been taking care of our clients in Central and South America since April 2022. She answers their inquiries in Spanish and English. Karina has her office near Miami, Florida. She therefore covers the appropriate time zones perfectly.

Summer vacations are just around the corner and various companies are shutting down their spring unit production. As long-time stops can cause problems when starting up the machines again, we suggest you to carry out the following instructions. This makes sure you don’t lose your programs, recipes or parameters.

Please note: These measures are for machines with Siemens control S5, S7, operator panels of Siemens and for the machine types FT-81, MDC-xy only. No actions are required for machines with a PC installed, such as the P-45x, P-460, PA-49x, and for the FPC-105 and FPA-300.

Method 1

Do not power off the 24VDC for the Siemens CPU and for the panel (this may cause that the long-term condenser gets unloaded and programs and/or recipes and parameters might get lost). You can switch off the breakers for the main motors and other consumers but ensure that the CPU is still powered up.

In case the connection with the software has been lost due to the long-term stop, you can reload the Siemens CPU with the different memory cards of the CPU. Please additionally export all your recipes to a local storage device, like a USB stick.

When a Buffer battery is installed, ensure that it is full.

Method 2

Take screenshots from ALL the pages on the screen, also from pages with parameters and so on. This is needed for a re-start of the machine in case you have lost recipes and parameters. Ensure that you have the correct program memory card ready.

Attention: Not all parameters are stored inside the recipes, therefore it is necessary to take screenshots from all the pages.

P-433 with B&R PC and installed S7 card: The buffer battery on integrated S7 card can get unloaded and parameters will get lost. Keep the PC constantly powered.

On restart of machines

Machines with CT drives (Digitax) and a dehumidification system: Switch on the machine, put emergency stop on and wait for at least 30 minutes to get the humidity inside down.

If you have any questions or if you are having trouble at the start up, we are happy to help you:

services(at)spuhl.com

COVID is still an issue, and the number of infections comes in waves. The travel restrictions introduced at the beginning of the pandemic are increasingly returning to normal and are being progressively reduced. We are happy to be taking a step towards normality again. This enables our technicians to help you more quickly and easily.

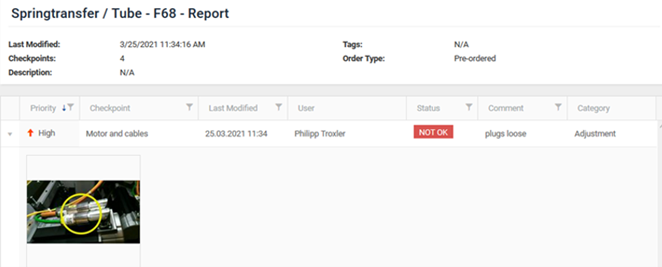

The long-established inspection logs for the service agreements are now fully digitized and are available to you at any time through Sepos.

The evaluations of the individual checkpoints are described in detail by our technicians along with images, text, and the priority. The results can be conveniently filtered for specific modules, helping you to plan maintenance work more efficiently.

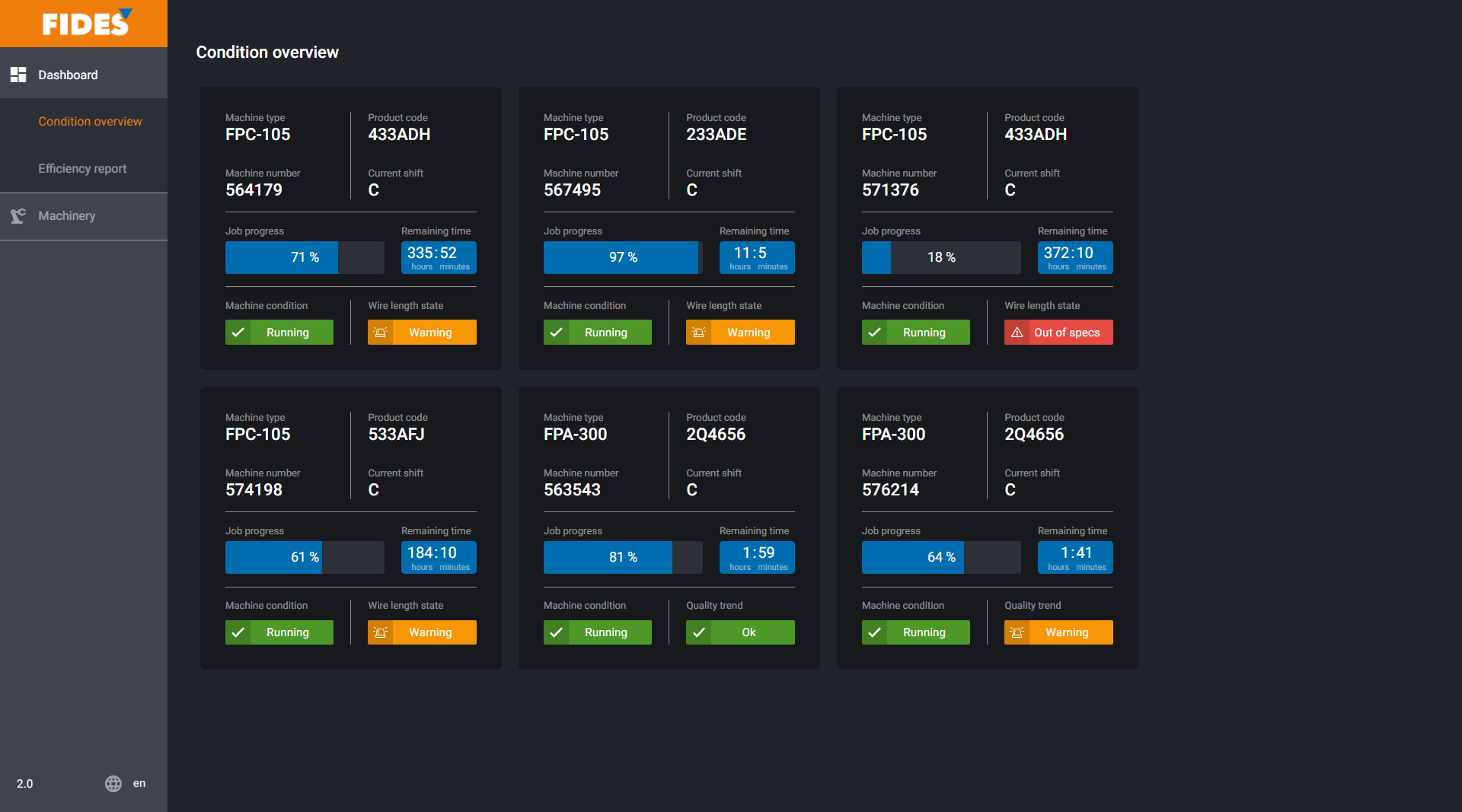

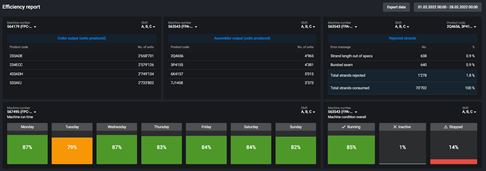

Our new smart service "Monitoring & Analytics" offers our customers a sophisticated production optimization platform. With its dedicated Reports & Dashboards, "Monitoring & Analytics" makes an important contribution to transparency in the product and process quality. "Monitoring & Analytics" provides an overview of the current status of Spühl and Fides machines, as well as detailed performance reports.

"Monitoring & Analytics" aims to provide broad-based optimization of machine performance in the production of innerspring units. The service offers added value particularly in the areas of raw material consumption and scrap reduction, and allows for quick and easy integration of relevant production data into our clients’ production reporting. Experience has shown that "Monitoring & Analytics" can save around USD 4,000 on wire per coiler machine. This service is currently available for the FPC-105 and FPA-300 machines, and other machines are being connected to the solution on a continuous basis.