Service Bulletin 1/2018

- Ready for the future!

- SEPOS returns

- Check safety guards

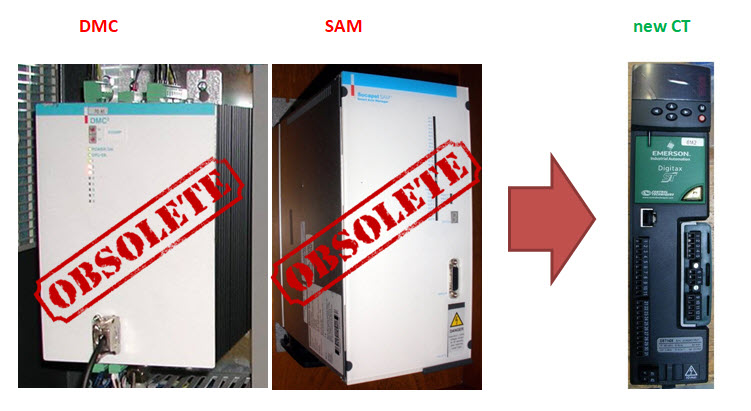

Spühl machines use a variety of electronic components that are now getting old. The availability, for example of DMC, TSX11, Sestep, etc., is becoming increasingly difficult, since their production has been partially discontinued for decades. The repair also becomes more difficult and takes more time.

Spühl, as your responsible and forward-looking supplier, has promptly developed conversion kits for most F, C and P series machines. This way, the old components can be replaced with the corresponding newest generations. Your advantages are clear:

• Ensuring a supply of spare parts

• Older machines can still be used reliably

• Newer components are generally less expensive than their predecessors

Please contact us if you want to bring your machine up to date. We would be pleased to make you a corresponding offer.

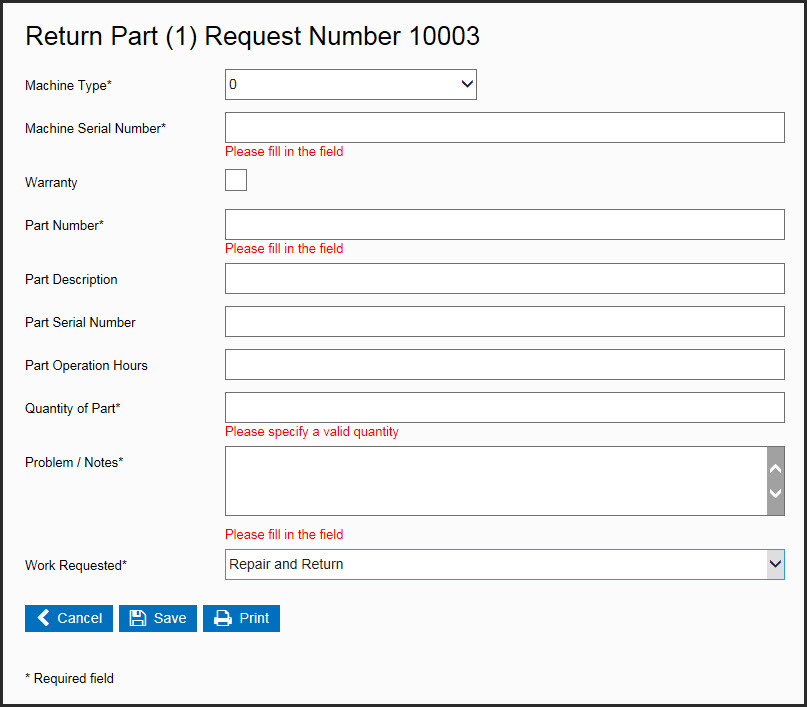

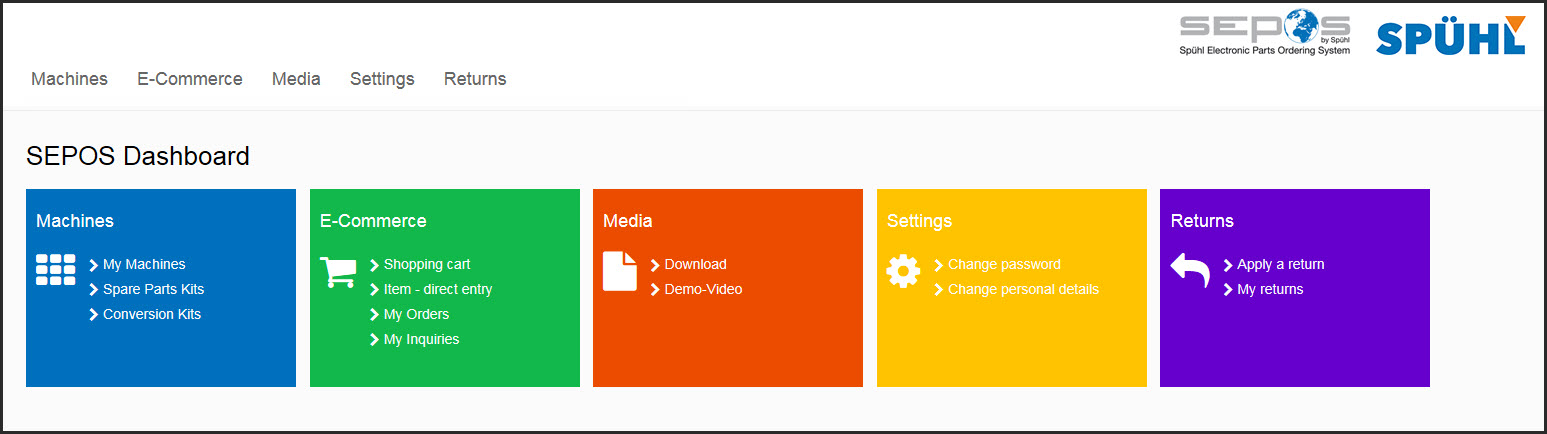

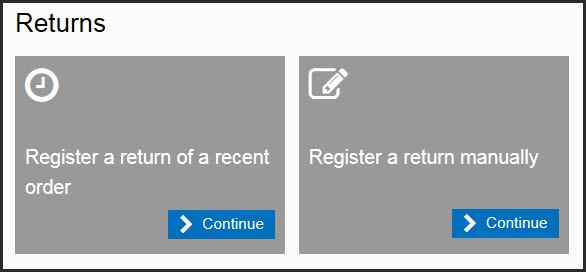

Since January 1st 2017, we have integrated the returns process into SEPOS.

Customers can thus register for returning material, which brings them the advantage of querying the status of their returns in SEPOS at any time.

The specified information on items to be filled in by the customer helps us keep the return process shorter by eliminating of any inquiries and clarifications.

Since January 1, 2018, returned goods without registration in SEPOS are not processed.

A brief guide is available for download in SEPOS.

Good employees are your most valuable asset! It is our and your responsibility to protect them as best as possible from accidents.

Our service technicians often find that protective devices on Spuhl- and Fides machines such as covers and safety switches are removed or bridged. This represents a high risk of accidents for your employees.

The following points must be observed:

- During start and automatic operation, the doors of the safety housing must always be closed and locked. Otherwise a malfunction is triggered.

- The safety devices can only be accessed with special tools or are secured with safety switches. Safety guards may only be accessed when the machine has been shut down and secured. It is prohibited to remove the safety devices or to render them inoperative. Malfunctions that may impair safety must be promptly eliminated.

- When protective doors are open, always first actuate the NOT-HALT (EMERGENCY STOP) button before adjusting the machine in order to prevent unintentional start-up of the drive mechanisms.

- If the machine is shut down with the NOT-HALT (EMERGENCY STOP) switch, it is prohibited to start the machine before a safety inspection has been conducted.

- Safety devices (e.g. covers) may only be removed after shutting the machine down and taking safeguards against reactivation of the machine (e.g. padlock on the main switch).